Pine chemistry refers to the co-products derived from the papermaking process that are upgraded into crucial ingredients used in a variety of goods important to our everyday lives.

Pine Chemistry

Pine Chemistry: A Chemistry with Environmental Benefits

Pine Chemistry Facts

- Pine chemistry has been around for approximately 100 years and is a long-standing example of bio-based chemistry that utilizes natural, renewable products from pine trees as raw materials.

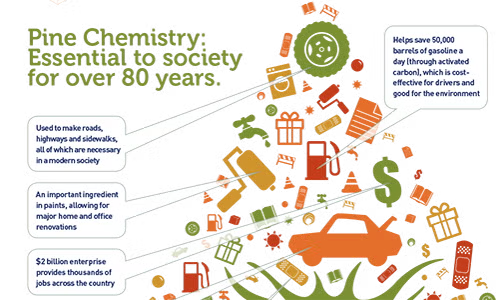

- The industry directly contributes to the US economy with almost $2 billion in shipments and employs almost 2,000 workers (2011).

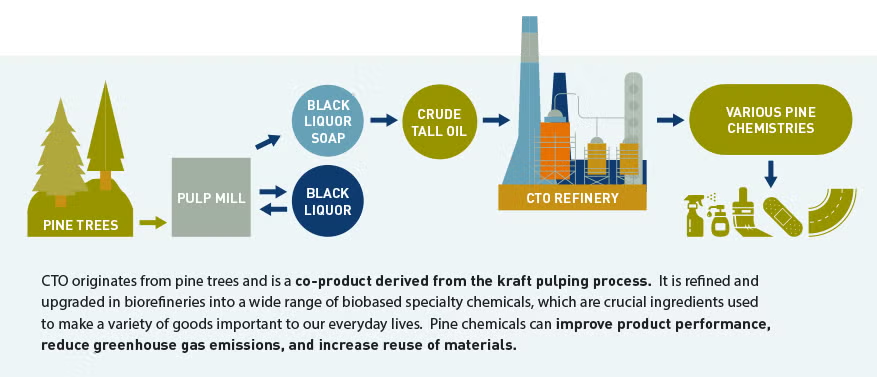

- Crude tall oil (CTO) is a prominent example of pine chemistry, and CTO refining is at the heart of a well-functioning bioeconomy.

- Crude tall oil (CTO) is a key pine chemical used to make many of the products that are important to our everyday lives. CTO can be further distilled into other pine chemicals such as heads, pitch, distilled tall oil (DTO), tall oil fatty acid (TOFA), tall oil rosin ester (TORE) and tall oil rosin (TOR).

- CTO can also be used as a feedstock in the production of biodiesel, often referred to as renewable fuel or advanced biofuel.

- The global availability of CTO will increase from 1.85 million tonnes per year in the year 2019 to 2.26 million tonnes per year in 2030. This increase is due to current and future softwood kraft pulp capacity expansions.

- Demand for CTO in bio-chemicals will grow from 1.48 million tonnes per year in 2019 to 1.56 million tonnes per year in 2030.

- Demand for CTO based biofuels for transportation will increase from 0.32 million tonnes per year in 2019 to 0.88 million tonnes per year in 2030.

- Project a growing deficit in the global CTO availability of 0.6 % in 2020 to 8% in 2030, due to increased biofuels demand.

Pine Chemistry Industry Group Members

Contact us

Media Contact

Tom FlanaginIndustry Group

Robert J. SimonFAQ

Pine chemistry refers to the co-products from the papermaking process that are upgraded into crucial ingredients in a variety of goods important to our everyday lives. This whole process ensures that the papermaking process is efficient and its co-products are not wasted.

The raw materials, crude tall oil and crude sulfate turpentine, are derived from evergreen, cone-bearing trees during the pulping process and are vital to the pine chemistry industry. The trees yield cellulose to make paper, and two co-products in the sap are further refined and upgraded to be used in ink, paints and coatings, adhesives, soaps and detergents, fragrances, chewing gum, and pine oil disinfectants. Other co-products, such as sawdust, are also used by the industry in environmentally friendly ways, including as a natural filter for everything from auto emissions to drinking water.

No. In fact, the pine chemistry industry has been around for over 80 years. It is a stable industry with a long history of contributing to goods used across the country and around the world. It is a long-standing example of bio-based chemistry or biorefining in that it utilizes natural, renewable products as raw materials.

Pine chemistry utilizes natural, renewable products as raw materials to make some of the most basic, yet necessary, items. The sap taken from trees (called crude tall oil), for example, is used in many products as a substitute for petroleum-based materials. And sawdust plays a crucial role in lowering automobile gas emissions. » Study points to the environmental benefits of pine chemicals (2013).

Pine chemistry makes important contributions to the American economy. It creates valuable and performance enhancing ingredients which are used in a variety of products.

Yes. There are policies being proposed in some states and at the national level that would classify these co-products as renewable biomass. This classification could lead to tax credits that provide an incentive to burn them for energy instead of allowing the existing pine chemistry industry to upgrade these products and use the renewable resources to their fullest potential without incentives from public funds. These government incentives potentially threaten the viability of the pine chemistry sector and their products. That is why we need to maintain a level playing field, where success depends on economic competition, not government incentives.

Government incentives that encourage companies to burn these important co-products from the papermaking process could trigger a market-distorting demand on the already scarce pine chemistry supplies. Since pine trees are not harvested for co-products, supply is inelastic, which means more demand will not lead to a greater supply. This could impact the goods that consumers frequently use and lead to greater reliance upon imported and fossil-based substitutes. Government incentives could subsidize the burning of these co-products as opposed to utilizing this renewable resource to make essential goods.

But this does not have to be the case. Policymakers should make certain there is a level playing field, which means companies are not incentivized at the expense of the pine chemistry sector and existing U.S. jobs.

There could be a number of likely consequences. Policies that incentivize the burning of pine chemistry co-products could waste a renewable resource, generate more greenhouse gases and potentially hurt a sector that is important to the economy. Without pine chemistry, American businesses could have to use more expensive ingredients that are not as environmentally friendly as pine chemistry. Furthermore, this impact to the healthy, domestic pine chemistry sector could result in the loss of jobs over many years for workers across the country. In many cases, those jobs may not come back.

While the pine chemistry industry is not opposed to providing energy incentives for new technology using underutilized biomass, it is opposed to establishing subsidies or mandates for scarce resources, such as pine chemistry, that could create inequities in the marketplace. That is why it is important to allow the market to determine the use of various raw materials.