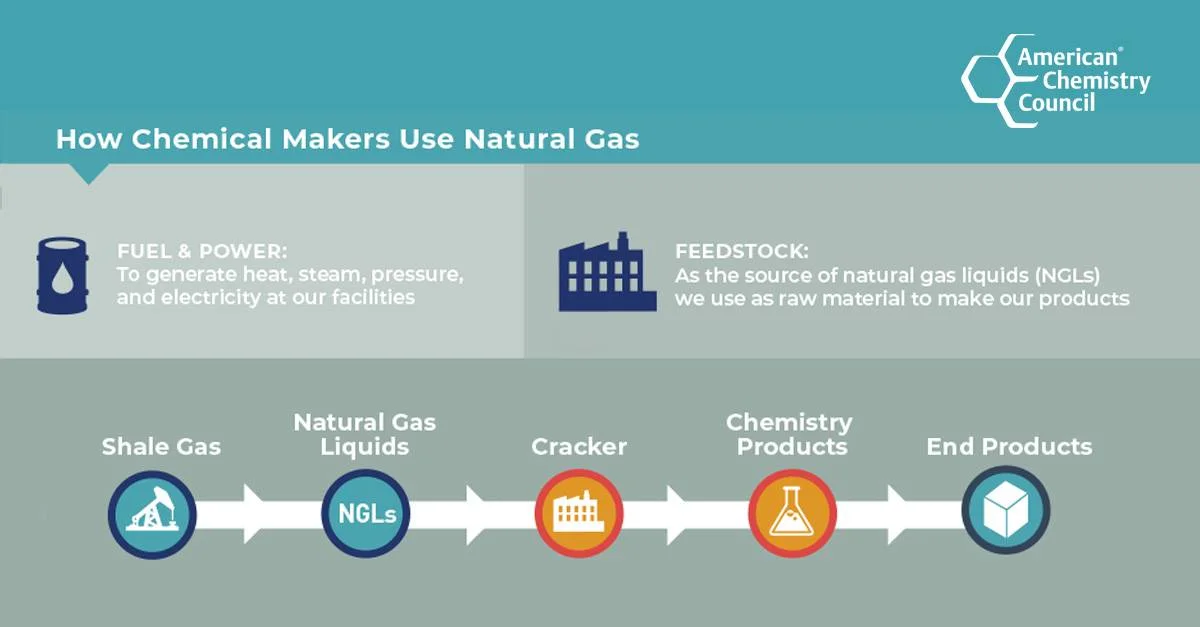

Natural gas has been employed in U.S. chemical manufacturing since the industry’s earliest days, and its importance has only grown over time. In this country, natural gas is used for fuel and power at chemical facilities, as a raw material for some chemicals, and as the source of natural gas liquids (NGLs) that are the main feedstock. Natural gas provides much of the energy used to run complex chemical operations. Today, it’s often the only adequate source of heat energy available for “cracking” and other heat-intensive chemical processes.

Shale Gas Was a “Game Changer”

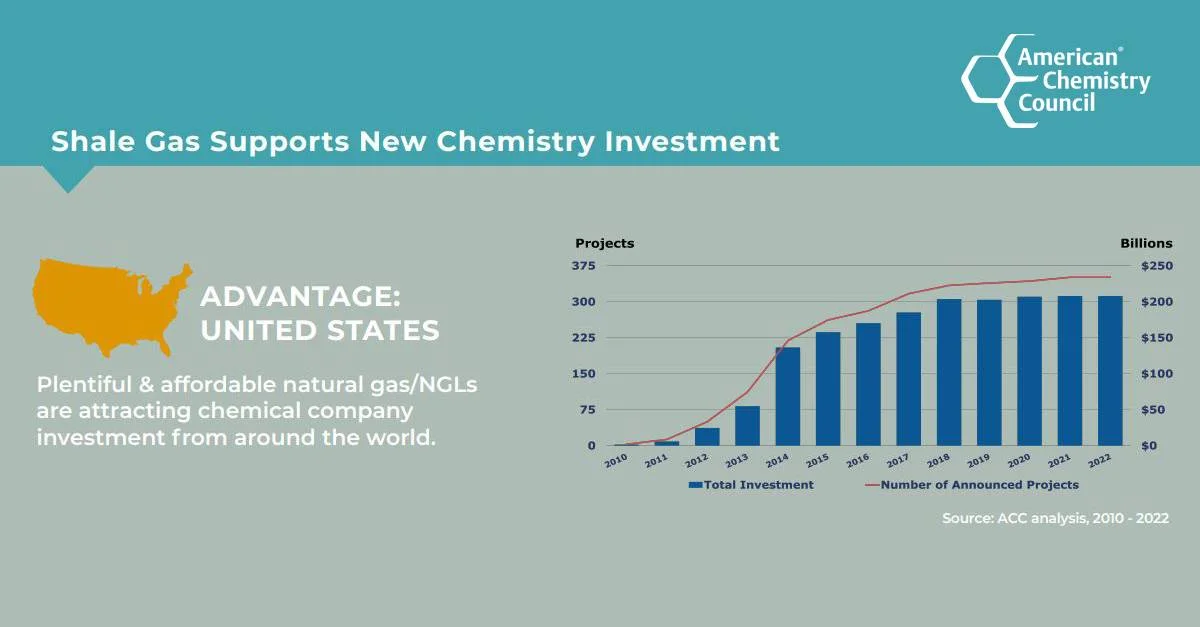

Shale gas was the lead factor in the U.S. chemical industry’s historic growth over the past decade or so. Plentiful and affordable supplies of natural gas and NGLs are motivating companies to build new chemical facilities and expand production in the United States. Since 2010, the industry has invested $109 billion; these 235 projects are completed and operating. Another 44 projects valued at $31 billion are under construction, while 72 projects valued at $68 billion are in the planning phase. Total investment is $208 billion across 351 projects. Fully 69% of the total spend is foreign direct investment or includes a foreign partner.

All of this chemical industry investment benefits the economy by generating employment, payroll, and output nationally and in local communities.

Chemistry Supports U.S. Manufacturing

Chemistry is positioned at the front end of the manufacturing supply chain. Chemistry products and technologies are used by major industries including automotive, building and construction, agriculture, computers and electronics, medical equipment and supplies, and household appliances. Virtually all manufactured goods are directly touched by the business of chemistry. Natural gas is important to several sectors of the U.S. economy.

Natural Gas Enables a Lower Emissions Future

Chemistry and plastics-based solutions and technologies are used to create many energy-saving and renewable applications that help reduce greenhouse gas (GHG) emissions. Climate solutions that rely on chemistry include solar and wind power, advanced batteries, electric vehicles (EVs), and high-performance building materials, to name a few.

Natural gas helped drive many of the emissions reductions achieved over the past decade and will play a crucial role in future progress. For example, natural gas contributes to a more reliable electric grid by serving as a back-up source for wind and solar generation. There is a growing focus on using natural gas pipeline infrastructure to transport a natural gas/hydrogen blend. Certain forms of carbon capture, utilization, and storage (CCUS) use natural gas, as do some forms of energy-efficient combined heat and power (CHP) systems. Chemical companies are among the industry leaders and participants in exploring the use of innovative lower-emissions technologies. To fully realize these opportunities, the right policies are essential.

ACC members are reducing their GHG emissions intensity, and many of those gains have come from transitioning from coal and coke to lower-carbon natural gas fuels. For many of ACC’s members, maintaining reliable, affordable access to industrial-scale supplies of natural gas and NGLs is critical to the competitiveness of U.S. operations as well as their long-term emissions reduction strategies.

Cracking: A process in which a long-chain molecule (or mixture of longer chain molecules) is broken down into smaller molecules to produce more useful chemicals. High-temperature cracking of hydrocarbons to produce olefins is referred to as steam cracking. When molecules are broken down in the presence of a catalyst, it is sometimes referred to as catalytic cracking. (Source: American Chemistry Council)