Silicones are among the world’s most important and adaptable materials, used in thousands of products and applications – from health care and personal care to electronics, transportation, construction, and energy. The backbone of silicon and oxygen atoms is the foundation of silicone chemistry and allows for the formation of siloxanes. Siloxanes are raw materials based on silicon, oxygen, hydrogen, and carbon and are the critical building blocks used to make silicone products.

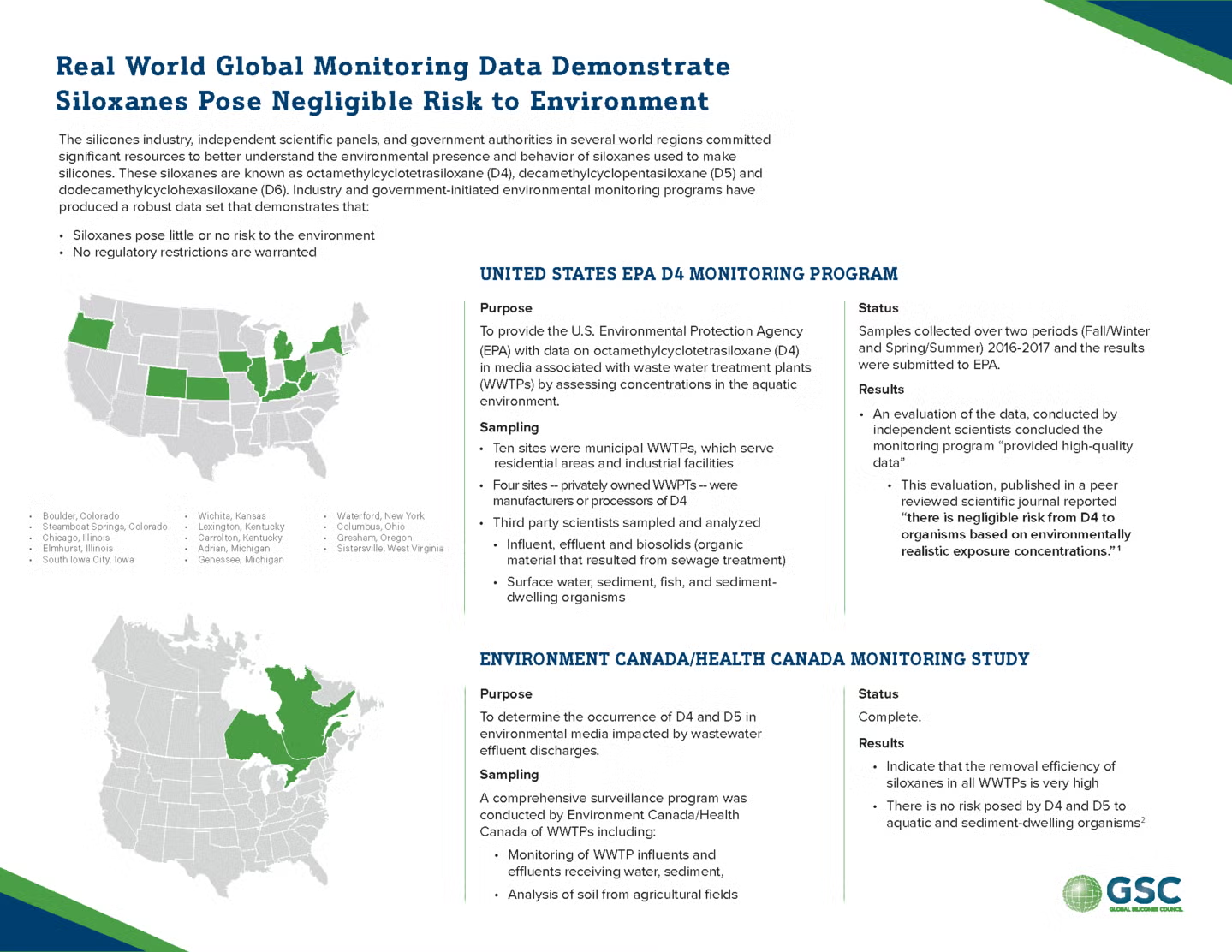

Siloxanes, including the cyclic siloxanes octamethylcyclotetrasiloxane (D4), decamethylcyclopentasiloxane (D5), and dodecamethylcyclohexasiloxane (D6) are among the most extensively studied materials used in consumer and industrial applications today. A host of independent scientists and expert scientific panels have confirmed siloxanes safety both for human health and the environment.

As part of the Silicones Industry’s commitment to the safety of its products and its sound product stewardship practices, the Industry has proactively conducted several siloxane modelling and monitoring initiatives. Computer models that can estimate a chemical’s physical-chemical properties and potential environmental fate and concentration are important tools for academics, industry, and regulators. Each of the siloxane materials have unique physical-chemical properties that differ significantly from the traditional organic chemicals for which most computer modelling programs have been developed. Thus, the Silicones Industry has collaborated with modelling experts around the world to customize the input parameters of these models based on the properties of the chemical being modelled.