Organic Peroxide Producers Safety Division (OPPSD)

OPPSD Pens a New Chapter for a Fire Protection Handbook

The Organic Peroxides Producers Safety Division (OPPSD) is excited to announce that the 21st edition of the National Fire Protection Association Fire Protection Handbook will include a new chapter on organic peroxides. The OPPSD contributed content which will be available in Section 6, Chapter 19 of the handbook. This new chapter highlights organic peroxides’ characteristics, commercial uses, hazards associated with transport, storage, and use, and gives the bases for preventive and mitigating methods to reduce risks while handling products. This material will provide helpful background for those involved in the design or operation of facilities covered under Chapter 14 of NFPA’s Guideline 400, Hazardous Materials Code. The hazards of organic peroxides and appropriate risk reduction techniques are unique. This information on potential hazards and safety practices will address some misperceptions about organic peroxide formulations and help companies work safely with this unique class of products.

Learn moreProduct Stewardship

Resources for safe handling, disposal, and transportation of organic peroxides.

Learn moreOPPSD Facts

Organic peroxides have several applications in the plastics industry, these include polymer synthesis, cross-linking, and polymer modification. All the processes are reliant on the free radicals which form when the organic peroxides decompose due to heat of chemical accelerators. The following operations are examples of those using organic peroxides:

- Organic peroxides are used to initiate polymerization. Free radicals allow monomer molecules to link into the chain structures that are called thermoplastic polymers. These polymers include low density polypropylene (LDPE), polystyrene (PS), and polyvinyl chloride (PVC), for example.

- Organic peroxides are used to make composite products like fiberglass reinforced plastic (FRP) using vinyl ester or polyester resins. Composites are used in strong and chemical resistant structures, like gasoline storage tanks.

- Organic Peroxides are used to vulcanize rubber compounds (elastomeric materials). Free radicals react with the rubber molecules to form radical sites which then form carbon-carbon bonds between the rubber molecules. The vulcanized rubber is highly stable thermally and gives low compression set at elevated temperatures. They are useful in automotive and aerospace applications, for example.

- Polypropylene is modified by adjusting the molecular weight and molecular weight distribution, also due to reactive free radicals generated from organic peroxides.

FAQs

Organic peroxides are organic substances which contain the bivalent -O-O- structure. They may be regarded as derivatives of hydrogen peroxide, where one or both hydrogen molecules have been replaced by organic radicals. Radicals are compounds that contain an unpaired electron. Organic peroxides are thermally unstable substances that undergo exothermic decomposition (the process of giving off heat when they decompose) to produce free radicals — radicals that are in constant search to bind with another electron — that serve a variety of purposes. This allows organic peroxides to be used in industrial chemistry, and other applications. Some organic peroxides are also strong oxidizers which allows them to be used in sanitation applications.

Organic peroxides have several applications in the polymer industry. These include polymer synthesis, cross-linking, and polymer modification. All the processes are reliant on the free radicals which form when the organic peroxides decompose due to heat or chemical accelerators. The following operations are some examples of those using organic peroxides:

- Organic peroxides are used to initiate polymerization. Free radicals allow monomer molecules to link into chain structures that are called thermoplastic polymers. These polymers include low density polypropylene (LDPE), polystyrene (PS), and polyvinyl chloride (PVC).

- Organic peroxides are used to make composite products like fiberglass reinforced plastic (FRP) using vinyl ester or polyester resins. Composites are used in strong and chemical resistant structures, like gasoline storage tanks.

- Organic Peroxides are used to harden rubber compounds (elastomeric materials) through heating. This process is called vulcanization. Free radicals react with the rubber molecules to form radical sites which then form carbon-carbon bonds between the rubber molecules. The vulcanized rubber is highly stable thermally and gives low compression set at elevated temperatures. They are useful in automotive and aerospace applications, for example.

- Polypropylene is modified by adjusting the molecular weight and molecular weight distribution, also due to reactive free radicals generated from organic peroxides.

OPPSD determine and develop appropriate testing methods to accurately measure hazards. This is the first step to risk mitigation.

OPPSD members interact with the agencies who develop regulations or guidelines for safe practices during transportation, storage and use of these materials. Examples include the U. S. Department of Transportation and the National Fire Protection Association.

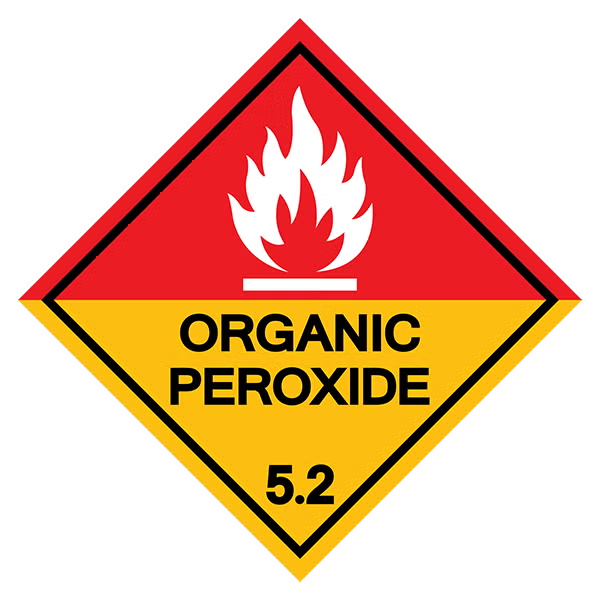

Safety in transportation includes limitation in package size and strength, maintenance of temperature control and avoidance of contamination.

Safety in storage prioritizes incident prevention. Manufacturers of organic peroxides follow strict safe handling procedures, which include storing organic peroxide formulations only in approved containers in well-ventilated areas, away from any sources of heat or flame and incompatible chemicals, and ensuring that these containers are kept within the recommended storage temperature range for the product.

In terms of human health and environmental impacts, consult the manufactures Safety Data Sheet (SDS) for the specific concerns and mitigation measures. Typical protective equipment includes eye protection and chemical resistant gloves, but some formulations may require the use of respiratory protection, in the absence of engineering measures.

Organic Peroxide Producers Safety Division (OPPSD) Members

OPPSD members work to address safety issues confronting the organic peroxide industry. They identify the hazards presented by mishandling of organic peroxides, determine and develop appropriate testing methods to accurately measure these hazards, develop safety practices, and establish communications surrounding safety practices for firms that manufacture, ship, handle, and store organics.

Join Industry Group

Interested in joining the Organic Peroxide Producers Safety Division?

Contact usView More Resources

View all related resources from this industry group.

Learn more